TURBIX Enerji ekibi olarak enerji üretim sektöründeki çeşitli kritik projelerde edindiğimiz deneyimle hizmet vermekteyiz. Aşağıda listelenen projeler, ekip üyelerimizin geçmişte aktif olarak katıldığı ve teknik katkı sağladığı çalışmalara örnektir.

İstanbul Doğalgaz Kombine Çevrim Santrali – A

2. Project: İstanbul Natural Gas Combined Cycle Power Plant-A

Location: İstanbul, Türkiye

Date: 2005-2024

The following maintenance and repair works have been carried out on three double-exhaust, two-cylinder, condensing type steam turbines manufactured by Siemens AG, installed in the plant

Scope of Work:

a- Minor Inspection

- Visual Inspections:

Visual examination of the turbine casing, connection points, insulation, and sealing systems. Checking for signs of oil leaks, steam leaks, or abnormal vibrations.

- Lubrication System Inspections:

Checking oil level, oil quality, and filters. Collecting oil samples for laboratory analysis (including particle content, water contamination, viscosity, etc.).

- Vibration and Thermal Analysis:

Performing vibration measurements and comparing them with historical data.

- Bearing Inspections:

Monitoring bearing temperatures, unusual noises, and lubrication condition.

- Rotor Free Rotation Check:

Verifying the free manual rotation of the turbine rotor, especially prior to initial startup.

- Bolt Torque Check:

Checking the tightness of critical connections using a torque wrench.

- Protection and Control System Testing:

Testing the turbine control system. Verifying the functionality of safety systems such as overspeed trip and low oil pressure trip.

- Exhaust and Steam Inlet Line Inspections:

Inspecting valves, actuators, and piping connections.

- Minor Cleaning and Greasing Works:

Performing minor cleaning tasks and applying lubrication as necessary.

b-Major Overhaul

Each of the steam turbines ST10, ST20, and ST30 has undergone a single major overhaul as part of the scheduled maintenance program

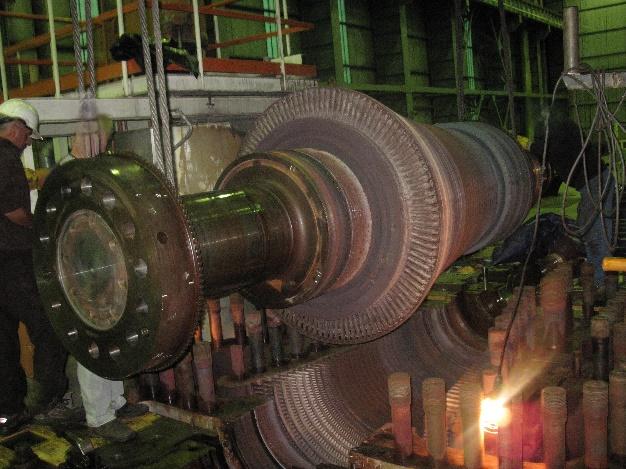

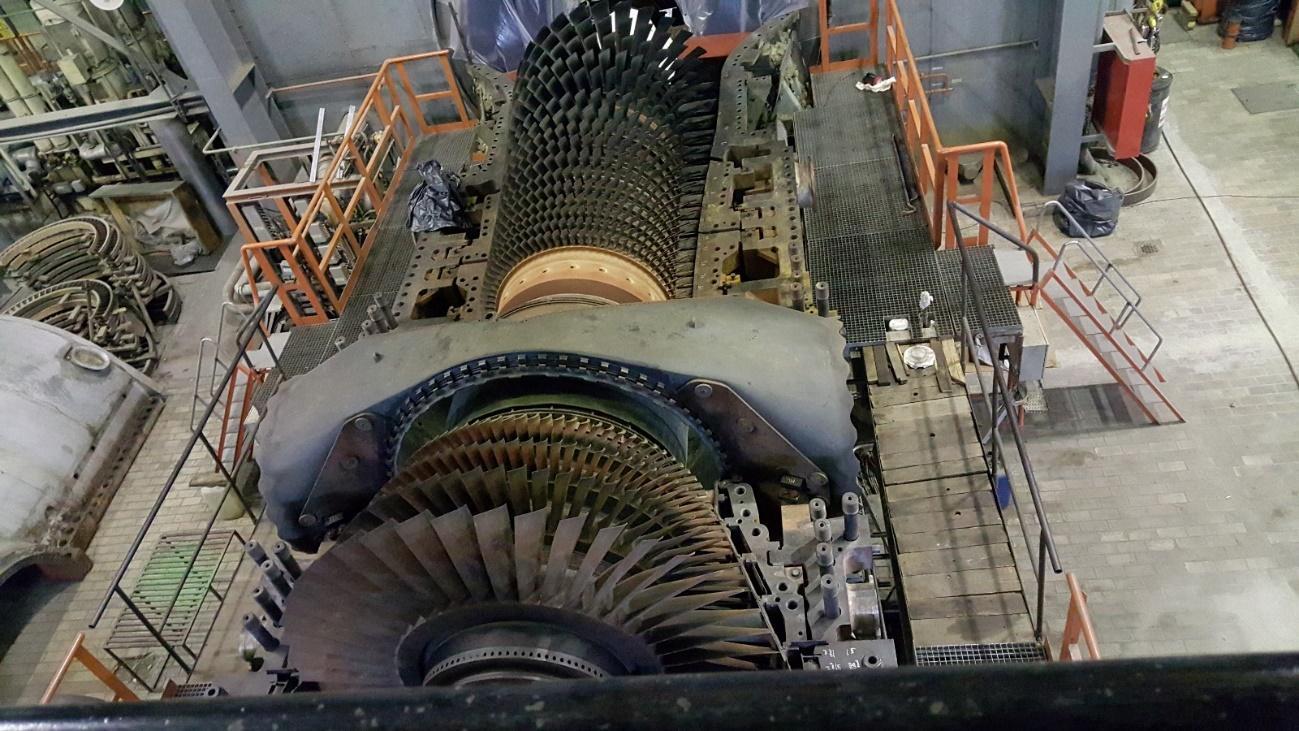

- Complete Dismantling of the Low Pressure (LP) and High Pressure (HP) Turbines:

The HP and LP upper casings were removed, and the HP and LP rotors were extracted.

- Inspection of Rotors, Stator Blades, Nozzles, Diaphragms, and Casings:

Non-Destructive Testing (NDT), including FPI and MPI, was performed to detect erosion, cracks, and thermal fatigue.

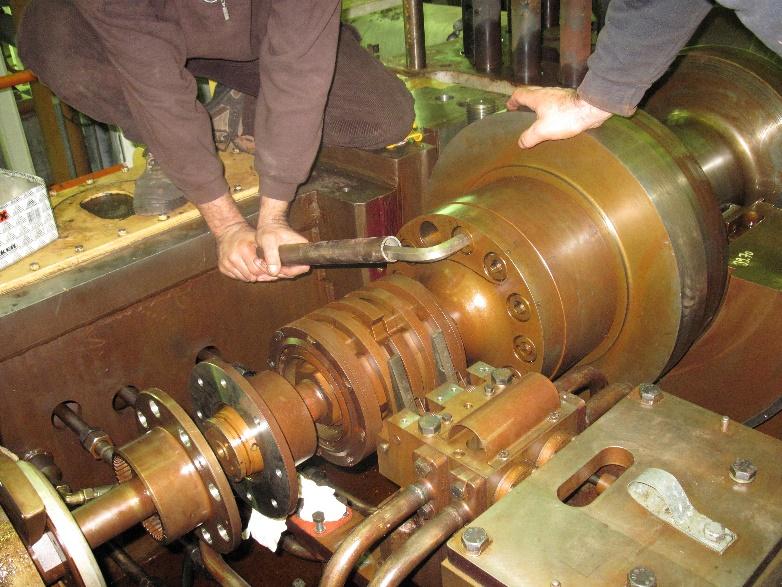

- Bearing Inspection:

All turbine bearings were inspected for wear, lubrication, and temperature conditions.

- Casing Sealing Systems:

Labyrinth seals and gland packings were inspected and renewed as necessary.

- Replacement of LP Last-Stage Blades:

Eroded last-stage blades in the Low Pressure section were replaced with new ones.

- Rotor Balancing:

Dynamic balancing procedures were carried out on the turbine rotor.

- Turbine Commissioning Tests:

Start-up and operational tests were successfully completed following the overhaul.

- Maintenance of Auxiliary Systems:

Vacuum system (condenser ejectors, vacuum pumps)

Steam bypass and emergency stop valves

Lubrication and control oil systems (Hydraulic Oil System)

Heat exchangers and coolers

Control system (governor and electro-hydraulic control units)

- Steam Turbine Generator Overhaul

As part of the major maintenance program, the following activities were conducted on the generator:

Detailed visual and electrical inspection of rotor and stator windings

Insulation tests including Tan Delta, Polarization Index (PI), DC resistance, and Partial Discharge (PD) measurements

Inspection of cooling (hydrogen), lubrication, and sealing systems

Rotor balancing, air gap measurement, and alignment operations

Maintenance of auxiliary systems (excitation system, brush-collector, dryer, etc.)

Comprehensive testing, measurements, and detailed reporting followed by successful commissioning

This comprehensive overhaul was successfully completed to ensure the generator’s safe, efficient, and reliable long-term operation.